Parallel Arm Closer, Tri-Packed, Adjustable Size 1-6, Thru Bolts (M54), Aluminum Powder Coat 689

$935.22

In stock

Corbin Russwin

The reliable and easy-to-install DC8000 series door closer is the perfect choice for high-use openings, meeting Americans with disabilities (ADA) and fire code requirements. The DC8000 series door closer offers a versatile, dependable and easy-to-install product, making it an ideal choice. The tri-pack assembly of regular arm, top jamb and parallel arm allows one closer to be stocked for multiple applications. A variety of features, including heavy-duty arms, cast-iron closer body and captured valves, ensure dependability and vandal resistance. Special mounting brackets and retrofit plates allow for quick installation in both new and retrofit applications.

Features:

ANSI/BHMA A156.4, grade 1

Multi-size spring power; adjustable 1-6

Non-handed

Cast iron case with seamless cold headed steel spring tube

Standard heavy-duty, forged steel arm

1-1/2″ diameter piston

Quick-Install mounting bracket standard

Stringent testing supports a long-life of reliability

Allows door to swing 180° for regular, top jamb and parallel arm mounting (conditions permitting)

Constructed with robust materials and internal components

Standard mounting regular or top jamb. Parallel arm or try-style packaging specify DC8210

Protects the door and frame from damage and reduces maintenance costs

Self-drilling screws standard

Arm configurations meet broad range of applications

Latching speed, closing speed and backcheck valves standard

Painted or plated finishes

Metal cover optional

30-year limited warranty

Specifications:

Spring Power: DC8200 series closers: multi-sized; fully adjustable sizes 1 through 6.

Handing: Non-handed.

Body: Cast iron case with seamless cold-headed steel spring tube.

Arm: Standard: heavy-duty forged steel.

Spindle: Cold headed heat-treated steel.

Piston: 1-3/8″ diameter; precision machined, heat-treated steel.

Springs: Chrome silicon wire.

Valves: Latching speed valve, closing speed valve and backcheck valve are standard. Delayed action valve optional. Delayed action preset for 20 seconds. Between 90° and 70° for all mountings. To order specify M71.

Seals: “O” rings.

Fluid: Standard high lubricity extreme temperature hydraulic fluid.

Degree of Opening: Up to full 180° opening standard for regular, top jamb and parallel arm mountings, conditions permitting.

Power Adjustment Arm Bracket: 15% adjustment standard for regular arm and top jamb (non-hold open only).

Tri-packed: DC8210 comes with screws, brackets and soffit plates to allow for regular, top jamb and parallel arm installations.

Cover: Standard: full ABS cover. Optional: full metal cover; specify M73 x hand.

Mountings: Standard: regular and top jamb. Optional mountings available

Mounting Bracket: Universal quick-install mounting bracket standard.

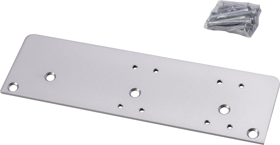

Fasteners: Self drilling and machine screws standard. Sleeve nuts and bolts (SNB) optional; specify M54.

Corrosion Protection: Painted protective coating on all metal surfaces for use in corrosive environments. To order specify M75.

Security Package: Includes heavy-duty parallel or regular arm, full metal cover and security Torx machine screws. Specify M87 x arm x hand. Available arms: A2, A3, A4, A5, A10 and A13.

Warranty: 30-year limited warranty.

Models:

DC8200: Regular Arm

Most common mounting, providing the greatest closing efficiency.

Closer is mounted on the pull side, with the arm almost perpendicular to the face of the door.

Arm bracket is attached to the door frame.

DC8210: Parallel Arm

Allows inside application of closer on out-swinging doors

Closer is mounted on the push side, with the arm parallel to the face of the door

Arm does not project from the opening

DC8220: Top Jamb

Closer is mounted on the frame on the push side, with the arm perpendicular to the face of the door.

Arm bracket is mounted on the door. Minimum 1-3/4″ (44mm) top jamb required.

Accommodates reveals up to 3-1/4″ (83mm).

DC8230: Pull Side Track

Closer is door mounted on the pull side; arm is connected to a frame-mounted track.

Maximum degree of opening is 100°.

Maximum closing power is size 4.

DC8240: Push Side Track

Closer is mounted on push side of door; arm is connected to a stop-mounted track.

Maximum degree of opening is 110°.

Maximum closing power is size 4.

Arm Options:

688F95 (Non-Hold Open)/688F77 (Hold-Open): Regular Arm

Used with regular arm mounting (pull side) and top jamb mounting (push side)

Available in painted or plated finishes

Non-hold open arm standard on the DC8200 closers

Hold open arm optional, specify closer x A1

597F52 (Non-Hold Open): Heavy-Duty Regular Arm

Recommended for high-use, high-abuse environments

Tamper-resistant, solid forged steel riveted arm

Mounted on pull side

Not available in plated finishes

Optional on DC8200 closers, specify closer x A10

688F95 x 188F41 (Non-Hold Open)/688F77 x 509F49 (Hold Open): Parallel Arm

Mounted on push side

Available in painted or plated finishes

Non-hold open arm combines regular arm with parallel arm mounting bracket

Hold open arm combines regular hold-open arm with parallel arm mounting bracket

Non-hold open arm standard, order DC8210 series

Hold open arm optional, specify closer x A1

689F02 (Non-Hold Open)/689F01 (Hold-Open): Heavy-Duty Parallel Arm

Recommended for high-use, high-abuse environments

Tamper-resistant, solid forged steel riveted arm

Mounted on push side

Not available in plated finishes

Optional on DC8210 closers

Non-hold open arm, specify closer x A3

Hold open arm, specify closer x A2. Hold-open range 85° to 110°

For use with overhead stops, specify closer x A13 (non-hold open only

689F03 (Non-Hold Open)/689F04 (Hold-Open): Heavy-Duty Reversible Backstop Parallel Arm

Recommended for high-use, high-abuse environments

Tamper-resistant, solid forged steel riveted arm (mounted on push side)

Field-reversible steel lug restricts degree of opening to protect door, wall and hardware

Requires both backcheck valves on closer

Shipped standard as left hand. Handing can be reversed in the field

Not available in plated finishes

Optional on DC8210 closers

Non-hold open arm, specify closer x A4. Door stop range 85° to 110°

Hold open arm, specify closer x A5. Door stop/hold open range 85° to 110°

691F96 (Non-Hold Open): Heavy-Duty Extra Clearance Parallel Arm

Recommended for high-use, high-abuse environments

Provides additional vertical clearance

Mounted on push side

Not available in plated finishes

Optional on DC8210 closers

Non-hold open arm only, specify closer x A13

Finishes:

USP/600 – Primed for painting

US3/605 – Bright brass, clear coated

US4/606 – Satin Brass, clear coated

US9/611 – Bright bronze, clear coated

US10/612 – Satin bronze, clear coated

US10BE/613E – Dark oxidized satin bronze-equivalent coated

US26/625 – Bright plated chrome

US26D/626 – Satin plated chrome

SBL/689 – Silver aluminum coated/sprayed

DBL/690 – Dark bronze coated/sprayed

LBL/691 – Light bronze coated/sprayed

FBL/693 – Black coated/sprayed

GBL/696 – Satin brass coated/sprayed

BSP – Black suede powder coated/sprayed

WSP – White suede powder coated/sprayed

Specifications for Corbin Russwin CORDC8210-689-M54

Other Specs

Alternate CodesDC8210-689-M54, DC8210689M54

CategoryDoor Closers, Surface Mount Closers, Surface Mount Door Closers

Door ApplicationDoor Closers

FastenersSex Bolts

Finish Code689

Finish ColorAluminum Powder Coated, EN, Sprayed Aluminum

MountingParallel Arm (Pull Side)

SeriesDC8000